Add to Cart

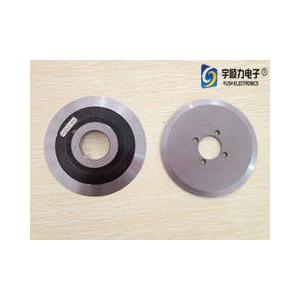

High Speed Circular Blades PCB Separation V Scoring Machine

Introduction

Separate machine blade is made from tungsten steel material . Round steel circular blade is made through precision grinding and polishing finishing . Its characteristics are high hardness and high wear resistance, sharp and durable. Its useful life is longer above 5 times than high speed steel blade, It is applied to feeding type and V groove plate cutting of the PCB printed circuit board.

Features of blade

1. the content of WC%:90.

2. the content of Co%: 10.

3. high hardness of HRA:92.4.

4. the density of g/cm3:14.4.

5. flexural strength MPa:3400.

6. the elastic modulus GPa:490.

Production

There are two steps of production process of the cutters: tungsten steel machine blade and blade molding finishing

A. The production process of blade blank material

Dosing (according to the applicable requirements to select tungsten carbide powder and cobalt powder) →fully mixing→crushing→drying→sieving→ then adding forming agent → drying again → sieving to get mixed material→ granulation→pressing→forming →(German imports low-voltage vacuum sintering furnace) low-pressure sintering → after sintered blank → testing (nondestructive ultrasonic inspection)→blank size accuracy test.

B. Blade precision processing.

clamping →fine grinding plane → fine grinding inner circle → fine grinding positioning holes→ external circle grinding→ rough edge→ fine edge→truing the outer circle→surface polishing→ microscope inspecting edge→ marking→packing clip to fine.

Descriptions

1. before using , test the depth of PCB board V groove and wear condition of the cutting tool. Accurately adjust the distance between upper and down cutter, so as to avoid the knife collision phenomenon.

2.Select reasonable cutting speed when cut board.

3. blade is razor sharp, Please pay attention to safety when you install it , so as to avoid unnecessary injury.

4. machine blade razor sharp, please install special Caution!, so as to avoid unnecessary injury.

5. The whole machine blade is made of high quality tungsten

steel which with high hardness and brittle , it is easy to fracture when meet the external impact, In addition, the tungsten steel cutting blade is thin, it is more easily broken when meet the external shock, so no beating during installation.